Keycap Materials: ABS, PBT, POM

Which component of a mechanical keyboard is the most recognizable? Of course, it's the keycaps! They are the first thing that catches your eye when you look at a keyboard, which is why most customizations start with them.

Besides their interesting appearance, keycaps also influence the tactile feel of your fingers (due to different surface textures) and the sound when typing. For example, keycaps made of dense plastic will produce a more hollow sound, while keycaps made of thin ABS plastic will have a more crisp sound. Some prefer silence, while others enjoy the satisfying click-clack.

Keycaps can even be made of materials like wood, silicone, or metal. However, the vast majority are made from several main types of plastic, each with its own advantages, disadvantages, and tongue-twisting names. Let's take a look at them.

ABS (Acrylonitrile Butadiene Styrene)

ABS is the most popular material used for manufacturing keycaps for mechanical keyboards. They melt at a relatively low temperature (around 105°C), making them easy and cost-effective to produce. ABS keycaps are also susceptible to UV radiation: they can yellow or even degrade when exposed to sunlight. It's best not to leave them out in the sun. The texture of ABS keycaps is not very pronounced; they feel smooth and slippery, just like LEGO pieces.

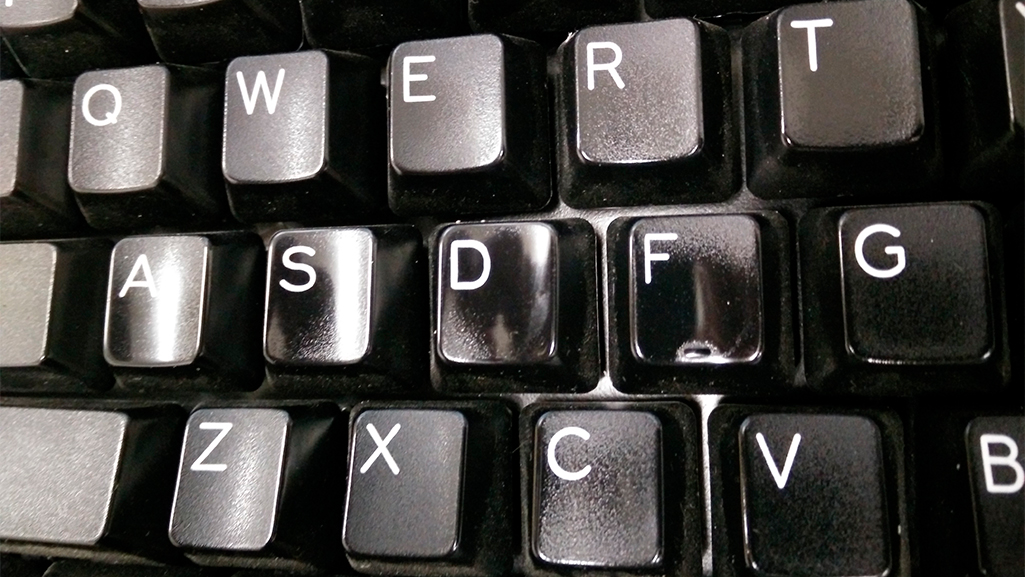

While the surface of ABS keycaps can be made slightly textured and pleasant to touch, it won't save them in the long run. Over time, the texture wears off, and the keycaps become shiny, like the bald head of One Punch Man. The poor resistance to wear is the strongest argument against ABS keycaps — they become shiny in the areas that are most frequently pressed.

During lively typing, the fingers "polish" ABS keycaps, resulting in an unpleasant shine. Perhaps one day you may even see your reflection in them.

PBT (Polybutylene Terephthalate)

A more rigid and heavier material, less popular due to its higher cost. It can be found on more expensive keyboards or custom keycap sets. The surface of PBT keycaps traditionally has a slight "textured" feel. They are not afraid of UV exposure, but what's even better is that they are practically resistant to wearing out, unlike ABS. In recent times, PBT keycaps are becoming increasingly common in mass production. Some notable brands that use PBT keycaps include Leopold, Ducky, Vortex, Mistel, and Varmilo.

POM (Polyoxymethylene)

Even less popular than PBT, POM is a material that is rarely used in mass production keyboards today, as it is significantly more expensive than ABS. Like PBT, it is rigid, durable, heavy, and resistant to environmental influences. It does not become shiny over time. In terms of texture, POM keycaps feel smooth, similar to ABS. One example of keyboards using POM keycaps is the Noppoo Choc Mini.1.